what causes a rod to break on a riding lawn mower engine

After a decorated week of work, you finally take time to give some overdue TLC to your garden. When it's time to spruce up your lawn, you hop on your riding mower merely to observe that information technology won't move. What could be the problem? More than importantly, can it exist fixed?

A riding mower volition non move forward or backward if there are issues with the drive chugalug, terrain, gears, hydraulic fluid, pressure switch, or key stock. Knowing what to look for and where to check tin brand the process of getting a riding mower moving once again much simpler.

These are the situations we will be addressing today, as we list the possible reasons why a riding mower won't move forwards or backward. In addition, we'll too betoken out solutions for each of these issues. Let's get started!

Contents

- 1 Reason 1: Mower Drive Belt Slipping Or Damaged

- 1.1 Set: Replace Drive Chugalug

- 2 Reason ii: Lawn Mower Stuck In Mud

- two.1 Fix: Employ Cloth Nether Mower Wheels To Regain Friction

- 3 Reason iii: Lawn Mower Stuck In Gear

- 3.1 Fix: Here A Professional person Tin can Save You Time And Coin

- four Reason 4: Aged Hydraulic Fluid In The Manual

- 4.one Ready: Supplant Fluid

- 5 Reason 5: Cleaved Seat Pressure Switch Restricts Motion

- 5.1 Fix: Replace Pressure level Switch or Seat

- 6 Reason 6: Air In Hydraulic Fluid Lines

- vi.one Fix: Remove and Store Hydraulic Fluid

- seven Reason 7: Lost bike primal stock

- 7.ane Fix: Supersede key stock

- 8 Concluding Touches On Riding Mowers Not Moving Forrad Or In Opposite…

Reason 1: Mower Drive Belt Slipping Or Damaged

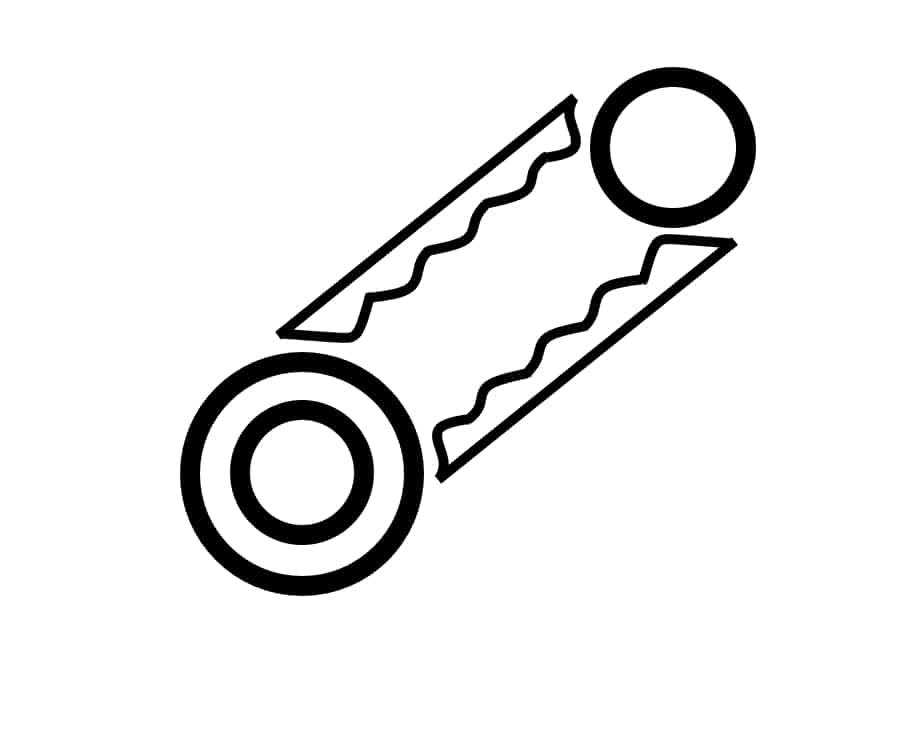

The drive belt is a key component in both ridden and push button mowers. However, it has the added do good of connecting a ridden mower's motor to the rear cycle axles. Essentially, information technology facilitates the conversion of horsepower to actual movement.

Mower drive belts slipping is major reason some riding mowers won't movement forward or in reverse. These belts connect the energy produced by the motor to the axle hooked to the bulldoze wheels. Old, excessively worn, or defective drive belts can slip instead of relay the energy required.

Naturally, the mower's mobility would be negatively affected if anything were to happen to the drive belt's integrity. Unfortunately, that is exactly what happens to these central components over time due to gradual wear. In one case the belt is completely snapped or footing, the beam loses its link to the motor and the mower fails to movement.

This is a common occurrence for mowers that have been in action for a while without ever getting a new belt. Disallowment extraordinary circumstances, new mowers won't see this problem for a while…simply always verify just in instance some failure or external wear hasn't occured.

Set up: Supervene upon Drive Belt

Somewhen, you will demand to supersede your drive belt. There are several options for you from Amazon and several aftermarket suppliers. Some manufacturers may also offer replacements as role of a warranty.

Replacing the bulldoze belt by yourself is a pretty simple process. It is important to conduct out all your DIY mower maintenance and repairs on a paved surface rather than on grass. You never know what small-scale parts could fall out. Safety gloves are also a good thought.

- The kickoff pace is to ensure that the ignition is OFF. Adjacent, open up the hood and detach the spark plug. This is washed by disconnecting a wire (or wires if the mower has 2 cylinders).

- The second step is to lower and detach the mower deck. This process involves the removal of the cutting blades, the blade belt, and mower deck supports.

- Next, you lot must remove the engine caster from the crankshaft and start detaching the drive belt from the bottom of the mower. Y'all have to then lift the mower seat, detach the battery and battery case to admission the transaxle caster near the top of the mower. Detach the other end of the chugalug and pull information technology out.

- The quaternary stride is to install your new drive belt. Loop it around the transaxle caster first before replacing the battery and instance. Next, loop the other end of the belt to the engine pulley.

- Finally, reinstall the mower deck and spark plug earlier giving the mower a whirl.

Reason two: Lawn Mower Stuck In Mud

It definitely can exist embarrassing when it happens, merely if a riding mower is used often enough, the odds are pretty good that you will find yourself in this situation. The process becomes exponentially more hard the larger the mower is.

A lawn mower stuck in mud is due to a lack of friction. The wheels are not able to create enough friction with the wet surface to move the mower forward or backward. In order to get the mower in motion again, other forms of material volition be needed under the bulldoze wheels.

The same principles of physics use with many surfaces:

- mud

- snow

- ice

- sand

- moisture inclines

The friction has been compromised that the tires can normally generate along the ground. The surface is movable or actively moving in a way that won't let the wheels to 'grip'.

This may sound like a simplified explanation, and that is because information technology is. This simple understanding makes the straight forward ready easy to understand.

Fix: Utilize Textile Under Mower Wheels To Regain Friction

This unproblematic solution works even better than you might imagine. The material needs to usually exist in 'sheet' form though in some instances piles of unconnected cloth will likewise work.

Using another textile that has potential surface friction tin then exist used by the tires along with the weight of the machine and even you lot to pull itself out of near slippery situations.

We have even at times had to rescue a big expensive mower that constitute itself stuck in very loose soil at the bottom of a steep inclined bank. Nosotros used various fabric and several guys running it from the back to the front of the slowly ascending mower to create a kind of moving span over the soggy soil.

Hither are some suggestions when looking for this friction substitute for you stuck mower:

Canvas Or Panel Material

- Hauling trailer decking sheets

- Chain link fence panels

- Composite or plastic trellis or lattice work panels

- Plywood or chipboard sheets

Other Material

- Sand (for icy applications)

- Gravel

- Large wood fries

- Lengths of concatenation

Reason iii: Lawn Mower Stuck In Gear

Some riding mowers are meant to have their gears changed while in movement and some are not. Some utilise a transmission clutch and some are more than automated in their operation. It is important to know what your machine'due south manufacturer designed the mower to do.

Backyard mowers stuck in gear are due to factors of either wear and tear or operator mistake in adjustments. Making improper adjustments in break, clutch, or transmission systems can all be culprits. This combined with normal deterioration of parts can cause mowers to be stuck in gear.

There are some instances where adjusting the suspension tension instead of replacing worn break disks or 'pucks' can increase the brake efficiency, merely will hinder the gear shifting procedure.

There are a multitude of issues this could be from the lubrication in the brake pins to worn parts connected to the transaxle. The make and model of your machine volition decide some of it and a thorough bank check of the continued parts will be necessary.

Fix: Here A Professional person Can Save You Time And Money

Giving a simple gear up to transmission related problems is not a helpful solution. At that place are many things that make up one's mind the class of activeness when dealing with transmission issues. Some are the make and model, and some are the condition of the parts involved.

In near issues not resolved past the other tips in this article, you will be dealing with a transmission repair, which is usually above the skills of the boilerplate dwelling owner or novice landscaper. If yous already know how to exercise this sort of repair, then this article was non intended for your issues in the starting time identify.

For those not skilled enough to bargain with transmission type repairs, a professional modest engine expert should be sought. In the long run this will save you fourth dimension, coin, and much of the pilus on the height of your caput.

Reason iv: Aged Hydraulic Fluid In The Manual

This is another common issue for riding mowers. Hydraulic fluid allows the manual to run smoothly and engage the mower's gears. Over fourth dimension, this fluid loses its ability to finer lubricate the manual, which would cause mobility issues.

Seasonal changes can accelerate this process. Winter is particularly problematic, and very cold areas might necessitate regular changes.

This also comes about with regular use through normal wear and tear. Merely like many of the other fluids in well-nigh types of engines, levels need to be monitored and entire changeover is needed on a regular basis. Some fluids require rare changes, while others need information technology more frequently.

Hydraulic fluid is one of those in the more rare category to become low, but modify is needed fifty-fifty if infrequently. If the fluid is leaking or running low constantly, this could definitely be the source of your mobility issue.

Set: Supersede Fluid

Again, this procedure can be done by professionals or at dwelling. The procedure involves letting the old fluid bleed out via the drain plug hole. Once drained, simply cascade in new fluid.

Proper disposal is another upshot and 1 reason many seek out the help of professionals. As with many fluids in motors of all types, only poring them down interior or storm drains is not an option.

Make sure you utilize the appropriate fluid for your mower. Consult your mower's manufacturer direct if you are uncertain.

Reason v: Cleaved Seat Pressure Switch Restricts Motility

For safety, a lot of riding mowers make use of a device called a pressure switch. This is essentially a sensor that restricts the mower'southward motility if at that place is no pressure in the seat (i.eastward., no i sitting in it).

While this is a very useful feature, information technology can be problematic if the switch starts malfunctioning. In such a scenario, the mower won't recognize seat pressure level and it volition restrict motion in any management.

Fix: Replace Pressure Switch or Seat

A new pressure switch should do the trick hither. Find and install a sensor that works with your mower model and examination if information technology works.

The seat could besides be a problem in rare circumstances. It may be dislodged from its regular position and fail to connect to the switch properly, resulting in a stationary mower.

To correct this, y'all must accommodate the seat to its rightful position. If the dislodging is a result of article of clothing, y'all should replace the seat.

Reason vi: Air In Hydraulic Fluid Lines

Aging isn't the only problem that plagues your mower's hydraulic fluid. Air bubbles are just every bit probable to disrupt your grass-cut. Air in the transmission lines will cause engine sputtering at showtime and, if y'all let the bubbles get bigger, the mower will eventually stop moving.

Fix: Remove and Store Hydraulic Fluid

The all-time mode to bargain with air bubbling is to forestall them. If left unchecked, this air tin can cause untold harm to your mower, so it is all-time to nip this problem earlier it causes serious impairment.

If you lot program on letting your mower sit idle for a while (i.east., during wintertime) make sure to bleed it of all hydraulic fluid. Allow the fluid drain into a container and store it safely. Supplant the fluid when it'southward time to use the mower again.

This tin can besides sometimes cure the air pockets that develop in the organisation. Make sure the fluid force per unit area is appropriate when you reinsert it and this should prepare any issues with air.

Reason seven: Lost bicycle key stock

Remember how nosotros mentioned working on a paved surface?

This is exactly why.

A key stock is a small piece of metallic (unremarkably stainless steel) that locks your mower's wheels to the wheel axles (on some mowers). These stocks tin hands autumn out when you remove or change your tires. They are very piece of cake to lose in grass.

Replacing a wheel without a key stock in place will effect in the beam spinning around in the wheel without engaging it to motility also.

Fix: Replace key stock

This trouble is elementary to solve. Simply retrace your steps to detect where you might have dropped your stocks. If yous cannot find them, yous must detect new ones.

Spin the affected wheel on its axle until you lot spot a gap (between the beam and wheel) you tin can fit a key stock in. Sideslip in the stock to seal the gap and lock the wheel in identify.

Final Touches On Riding Mowers Not Moving Forwards Or In Reverse…

Hopefully these suggestions can help you fix your riding mower mobility issues or at least send you lot down the right path. There are many ways that this annoying problem can occur.

We only want to outset upwards or mowers and become to piece of work. Life doesn't always work that smoothly. If you find yourself trying to troubleshoot this trouble, try each of these avenues.

Y'all may exist surprised to find that something simple can set the issue earlier taking your mower into a professional person.

References

https://www.youtube.com/watch?5=fnhenk37KcI&t=7s

https://upgradedhome.com/hydrostatic-mower-will-not-movement/

Source: https://lawncaregrandpa.com/7-reasons-why-a-riding-mower-wont-move-forward-or-reverse/